Electromechanical solutions for automation technology

SINADRIVES LINEAR MOTOR STAGES

As a competent partner in electromechanical solutions, SINADRIVES provides innovative products for fast and precise positioning.

Thanks to Standart Plug & Play linear units and our direct drive technology, we can offer customized and flexible solutions, for packaging, plastics, pharmaceutical, or photovoltaic sectors.

Our products: electrically driven linear axes and rotary table systems

Discover our specialities: linear motion solutions with applications for all types of industry.

Self-Assessment: enhance your machine’s performance with linear technology

Are you involved in automating machines with linear or rotary movements? Are you a manufacturer looking for low-maintenance solutions that increase productivity and reduce manufacturing costs?

If so, get in touch with us or take the short self-assessment in the E-Book (on the right). With a few quick questions, you’ll evaluate your needs and discover suitable electromechanical solutions for each of these needs, including linear motor stages, multi-axis systems, rotary tables, components, or entirely custom special solutions.

Personalized Inquiry: tailored solutions for businesses in the realm of linear technology

The implementation of customer-specific solutions in the field of linear technology is one of the core competencies of SINADRIVES. Experienced product developers work together with the customer to find the best and most economical solution.

At the same time, in addition to the large selection of our standard products, we can offer special solutions. This can be done from the small modification of a standard product to the development of an independent individual solution. The concept of the individual solution supports our customers in the design, construction and assembly. The application is implemented safely and economically with our products and can then be completely delivered by us.

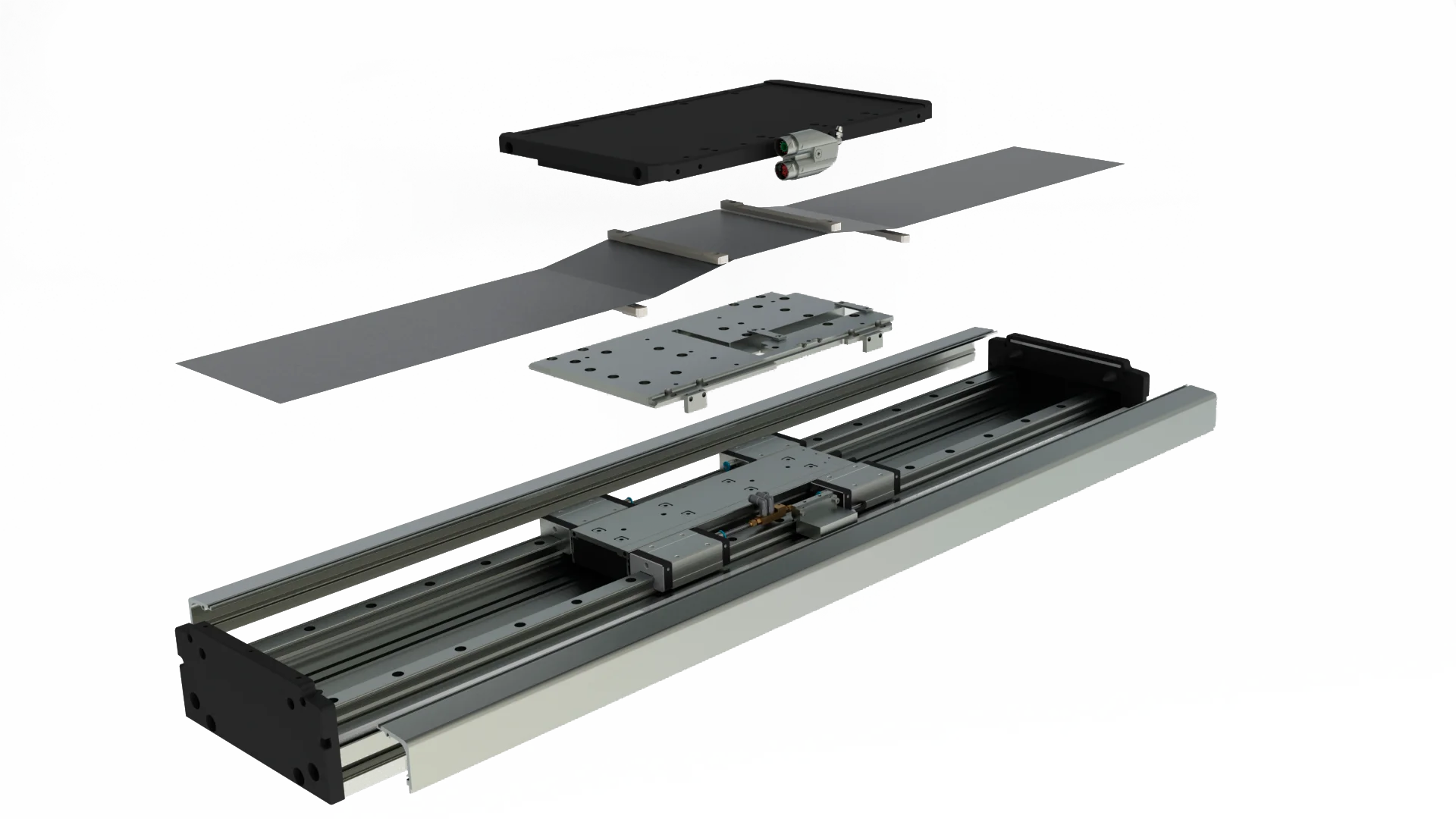

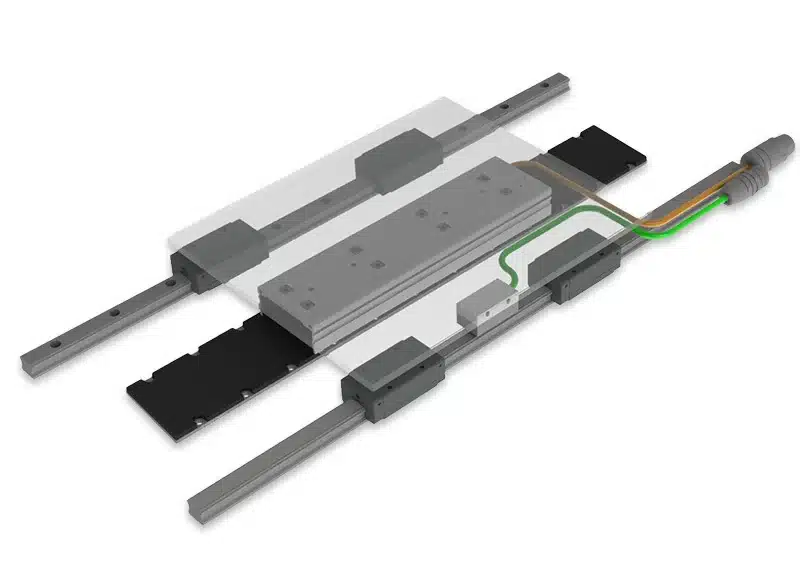

All of our linear motor units contain the following components of a linear motor stages: base profile, linear motor, magnets, guide rail, measuring system and connector.

1- Inquiry or Need

Identification of the need, first contact with the SINADRIVES team.

2- Quick feedback

Quick response from our team and analysis of the machine’s requirements.

3- Value-added proposal

Sending of the customized proposal and subsequently the solution in 3D format.

4- Short delivery time

The solution is prepared in a reduced time frame and delivered to the agreed location.

Reduce assembly and internal inspection times with SINADRIVES deployment processes, systems, and prefabricated assemblies. Benefit from the market leader’s experience for all your linear and rotary motions. Discover the industrial sectors already utilizing our technology!

Sectors that are already using our technology

Below are some examples of the diverse processes in which machinery manufacturers are successfully implementing the use of linear motors and rotary tables:

Electronics and semiconductors

Supply chain automation

Laser cutting technology

Food and beverage processing

Life Science, health and biopharma

Packaging and labeling systems

Pharmaceutical, medical and healthcare

Defense and military applications

Quality control systems

Automotive and aerospace

Printing and scanning machinery

Renewable energy and solar industry

Research and development

Textile manufacturing and production

Robotics and industrial machinery

How does a linear motor work?

Its versatility and distinctive characteristics make it a valuable option across a diverse array of applications, where precision, efficiency, and reliability are essential during linear motion. The linear motor capitalizes on the same fundamental principle as rotary motors, employing the interaction between magnetic fields and electric current to generate a force that propels linear movement:

Graphic representation exemplifying the conversion from a rotary motor to a linear motor.

Accessories for linear motor axis

SINADRIVES has all the necessary accessories and add-ons for our linear motor axes to easily integrate into the final application, reducing costs and development time resources for specific developments, and adapting the solution to the requirements. These are some of the complementary accessories for our linear motor solutions:

Get Social