Hi mechatronics fans!

Welcome to this new post in our Sinadrives blog.

March 2025

Rotary tables play a crucial role in precision motion control, providing accurate positioning, high torque, and smooth operation in automated systems. When integrated into rotary tables and multi-axis configurations, these motors enable greater efficiency and reliability across multiple industries.

This article explores specific applications where rotary motors make a measurable impact on productivity and precision.

1. Precision Machining and CNC Systems

In machining applications, rotary motors help achieve high accuracy, repeatability, and vibration-free operation. Rotary tables with direct-drive motors eliminate backlash, making them ideal for 5-axis milling, grinding, and turning.

- Aerospace Manufacturing: Rotary tables allow for the machining of turbine blades and structural components with micron-level precision.

- Improved Surface Quality: Direct-drive motors ensure smooth motion, reducing vibration and improving the surface finish.

- Higher Productivity: Multi-axis configurations enable simultaneous machining, reducing cycle times and increasing throughput.

2. Semiconductor Manufacturing

Semiconductor production requires ultra-precise motion control for wafer handling, lithography, and inspection processes. Rotary motors provide the high resolution and stability necessary for these operations.

- Wafer Inspection: Rotary tables allow for precise angular positioning, ensuring accurate alignment for imaging and defect detection.

- Lithography Systems: Multi-axis setups control the movement of masks and substrates with extreme accuracy, critical for microchip fabrication.

- Contamination-Free Design: Direct-drive rotary motors minimize mechanical wear and particle contamination, making them ideal for cleanroom environments.

3. Robotics and Industrial Automation

Rotary motors enhance robotic precision and flexibility, especially in pick-and-place, assembly, and welding applications. Their compact size and high torque density make them ideal for space-constrained automation setups.

- Automated Assembly: Rotary tables help precisely orient components, reducing errors and improving production speed.

- Industrial Welding: Multi-axis systems combined with torque motors enable smooth, controlled movements, ensuring consistent weld quality.

- Compact and Efficient: Direct-drive rotary motors improve response time and energy efficiency, reducing operational costs.

4. Medical Device Manufacturing

The medical industry relies on high-precision motion systems for manufacturing surgical instruments, implants, and diagnostic equipment. Rotary motors provide quiet, stable, and vibration-free motion essential for these applications.

- Orthopedic Implants: Rotary tables enable complex machining of custom implants with high accuracy.

- Laser Cutting and Micro-Machining: Multi-axis systems offer precise control for microscale manufacturing.

- Medical Imaging Equipment: Rotary motors help reduce vibration and noise in devices such as CT and MRI scanners.

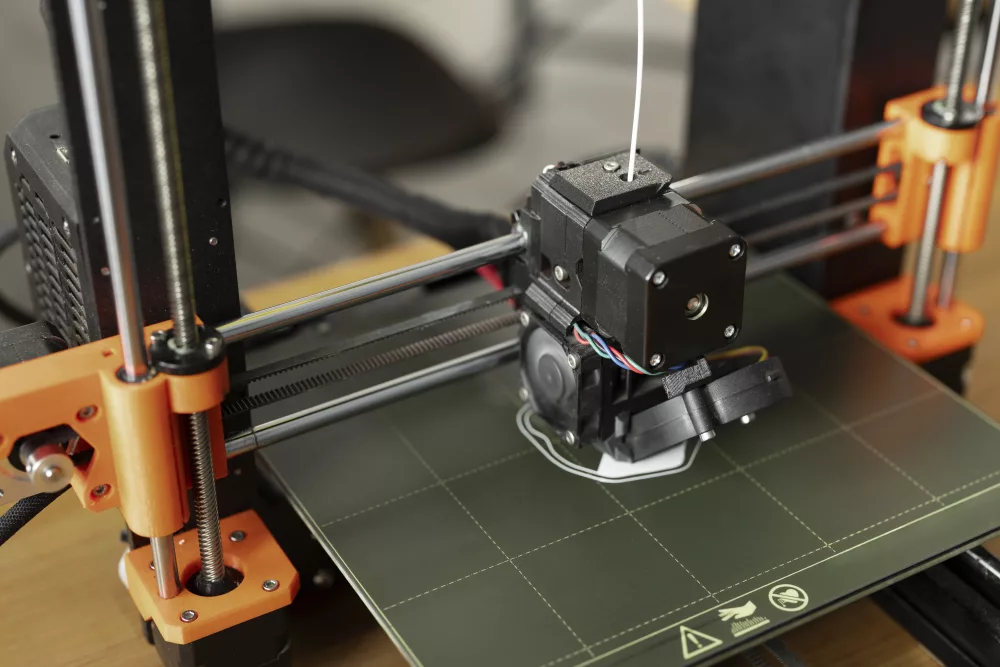

5. Additive Manufacturing (3D Printing)

Rotary motors play a critical role in metal and polymer 3D printing, ensuring precise material deposition and alignment.

- Enhanced Print Quality: Rotary tables allow for accurate positioning, improving layer consistency in printed parts.

- Continuous Printing: Multi-axis systems enable seamless movement, eliminating manual adjustments and reducing downtime.

- Complex Geometries: Rotary motion allows printers to create intricate designs that would be difficult with linear-only systems.

Conclusion

Rotary motors are essential for improving precision, efficiency, and reliability across multiple industries. Whether in CNC machining, semiconductor manufacturing, robotics, medical device production, or 3D printing, these motors enable advanced automation and optimized performance.

At SINADRIVES, we specialize in high-performance rotary motors designed for demanding industrial applications. Our motion control solutions help businesses achieve greater accuracy, efficiency, and long-term reliability.

To learn more about how our rotary motors can enhance your applications, visit SINADRIVES today.

Get Social