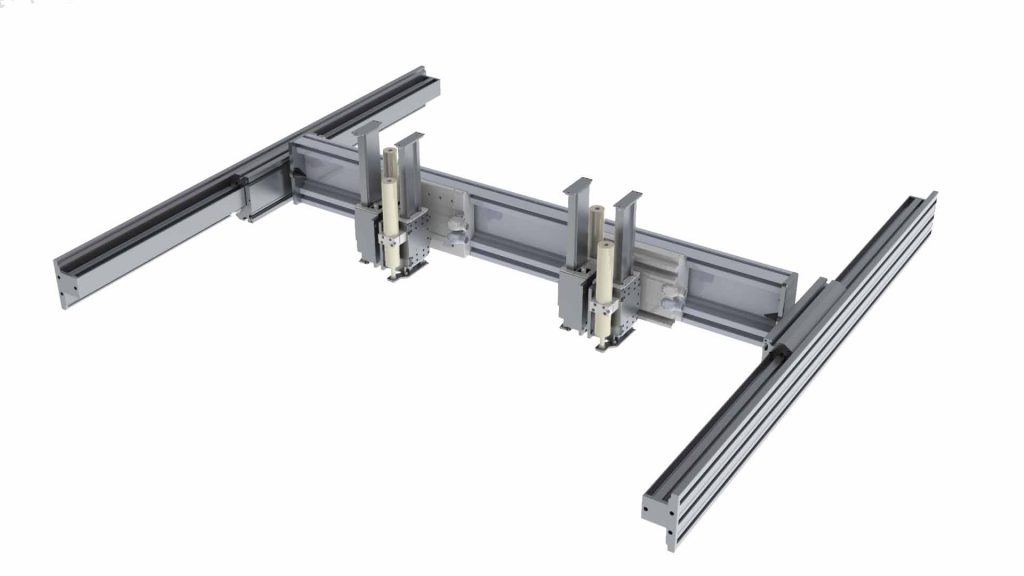

From drive technology to simple linear modules and complete multi-axis systems

SINADRIVES multi-axis systems consist of combinations of directly driven linear modules and differ in the type, size and arrangement of the combined axes. Depending on the automation task, two-axis combinations or three-axis portals are used. Systems are available in different sizes depending on the application requirements (load, stroke, dynamics and speed of positioning).

Sectors that are using our technology.

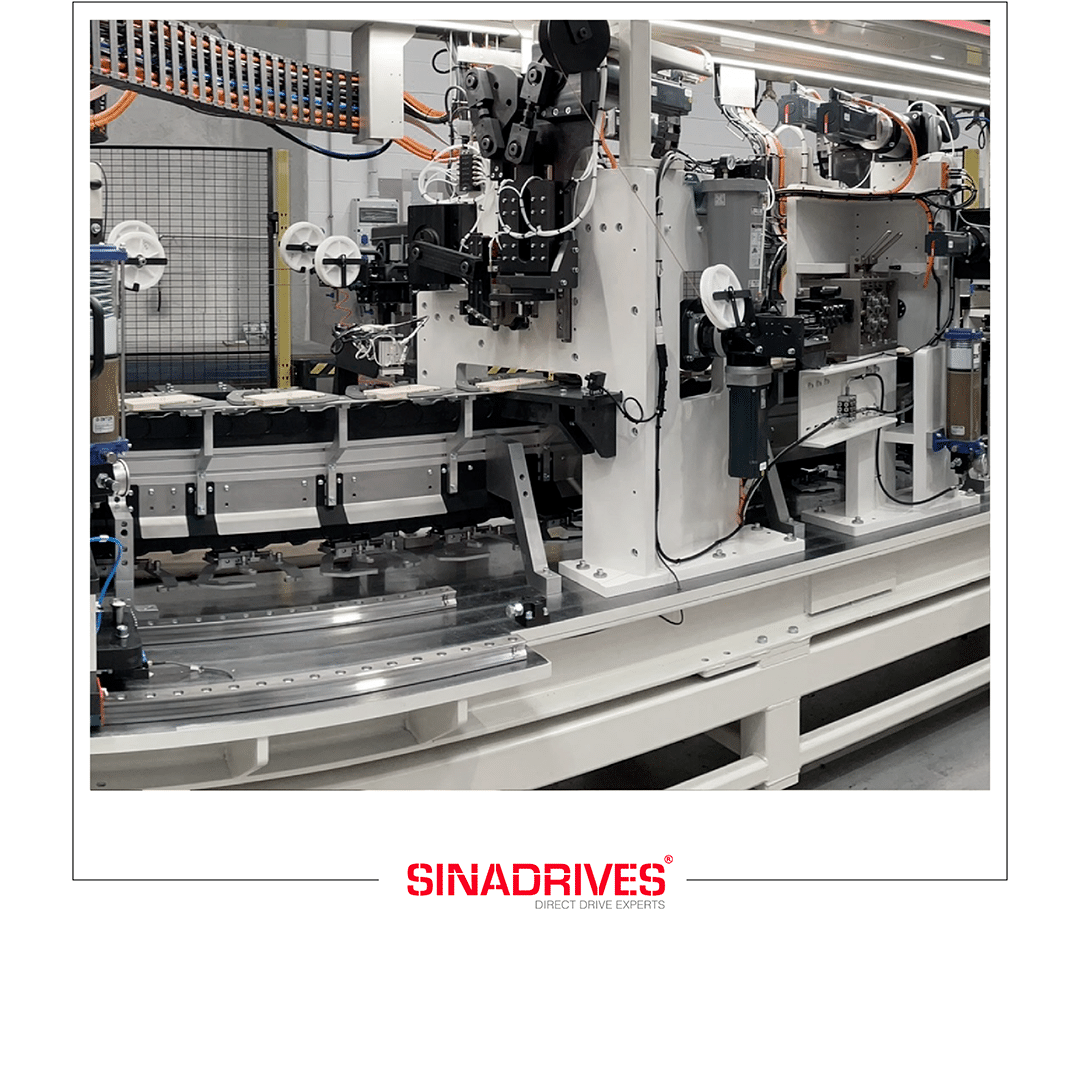

Below are some examples of the diverse processes in which machinery manufacturers are successfully implementing the use of linear motors and rotary tables:

Electronics and semiconductors

Supply chain automation

Laser cutting technology

Food and beverage processing

Life Science, health and biopharma

Packaging and labeling systems

Pharmaceutical, medical and healthcare

Defense and military applications

Quality control systems

Automotive and aerospace

Printing and scanning machinery

Renewable energy and solar industry

Research and development

Textile manufacturing and production

Robotics and industrial machinery

Axis systems offer at least two linear directions of movement for exact positioning. There are different series for different target applications. A high level of positioning and repetition accuracy and proper movement dynamics form the basis for successful system integration. Multi-axis systems allow extremely precise machining and positioning processes with extremely short control cycles.

DIRECT DRIVE EXPERTS

Advantages of a gantry system with linear motors

Compact X-Y precision multi-axis system, very good force-to-volume ratio, 1μm repeatability, high performance, high precision, short cycle times, precise and controlled movement and positioning, modular automation system.

The high level of electronics integration not only reduces the space required, but also the material and installation costs, compared to conventional solutions.

Extremely compact shaft systems support the space-saving construction, thereby optimizing the costs of cabinets and control systems. Installation and commissioning are quick and easy, guaranteeing further cost reduction.

Get Social