These linear motor stages are great for compact applications.

Repeatability (module): ± 5 μm

Max. Speed: 9 m/s

Max. Acceleration: 71 m/s2

Max. Length: up to 6.000 mm

This linear motor unit is ideal for compact applications with limited space.

Repeatability (module): ± 10 μm

Max. Speed: 9 m/s

Max. Acceleration: 200 m/s2

Max. Length: 1000 mm

Linear modules with ironless motors, the moving carriage is very lightweight for applications with acceleration of up to 200 m/s².

Comparison between linear motor ironcore and ironless modules

The MCE3 and MLU3 stages have been designed to cater to various industrial applications, offering distinct specifications and features to meet the specific needs of each project. Below is a summary of the key characteristics of each model:

| Ironcore | Ironless | |

|---|---|---|

| Maximum Speed | 9 m/s | 9 m/s |

| Maximum Acceleration | 71 m/s² | 200 m/s² |

| Protection Level | Standard | Standard |

| Encoder Protocols | Incremental: 1 Vpp TTL |

Incremental: 1 Vpp TTL |

| Maximum Length without Joints | 6000 mm | 3000 mm |

| Suitable for Clean Room | No | No |

| Guidance System | Double guide | Single guide |

Both the ironcore and ironless models offer versatile and efficient solutions for a wide range of industrial applications. The choice between these models will depend on the specific requirements of each project, including the desired speed, stroke length, and necessary protection level. With these advanced module options, customers can harness maximum performance and precision in their industrial applications.

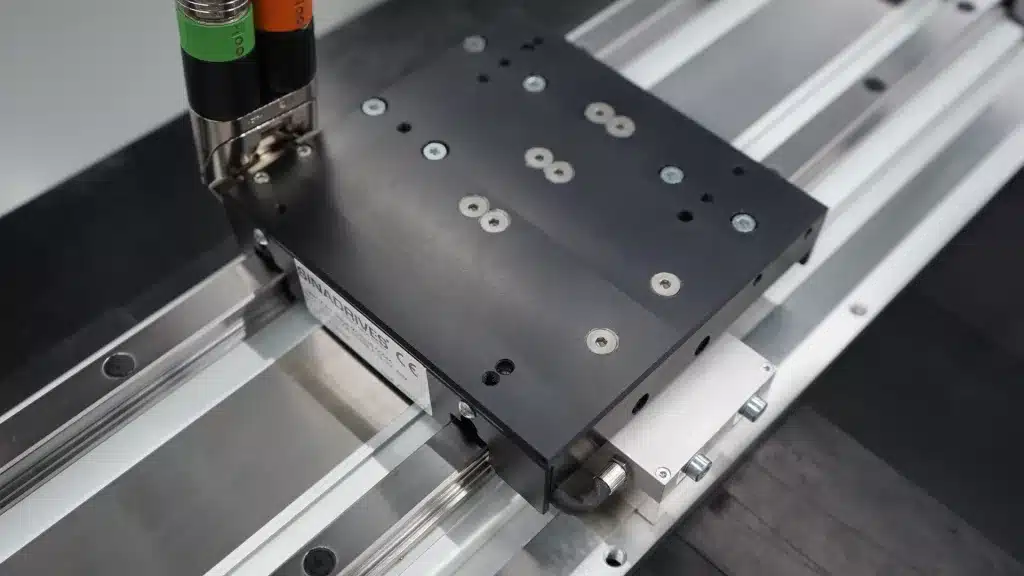

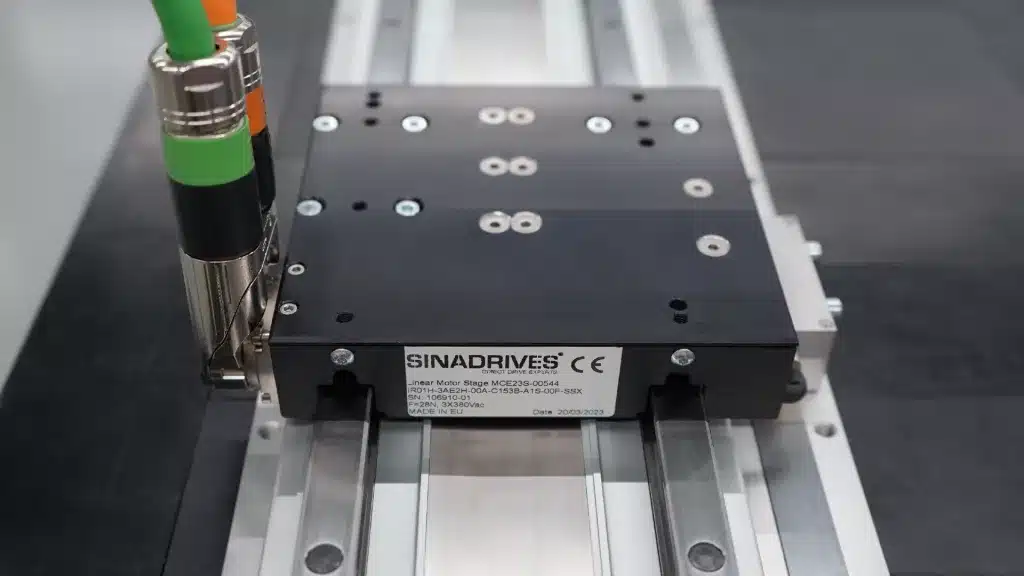

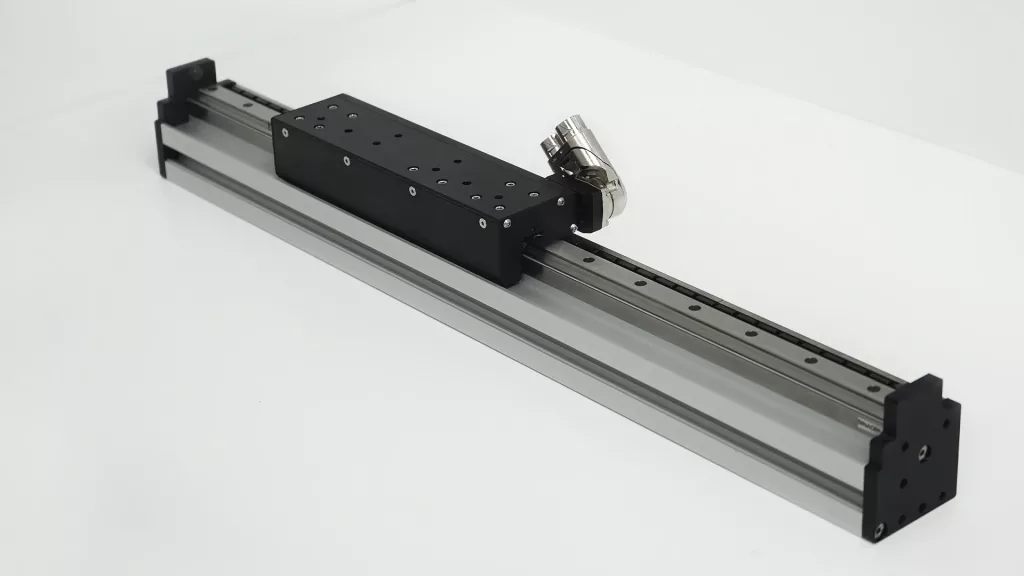

Ironcore linear motor stage

Ironcore linear motor stage

Ironcore linear motor stage

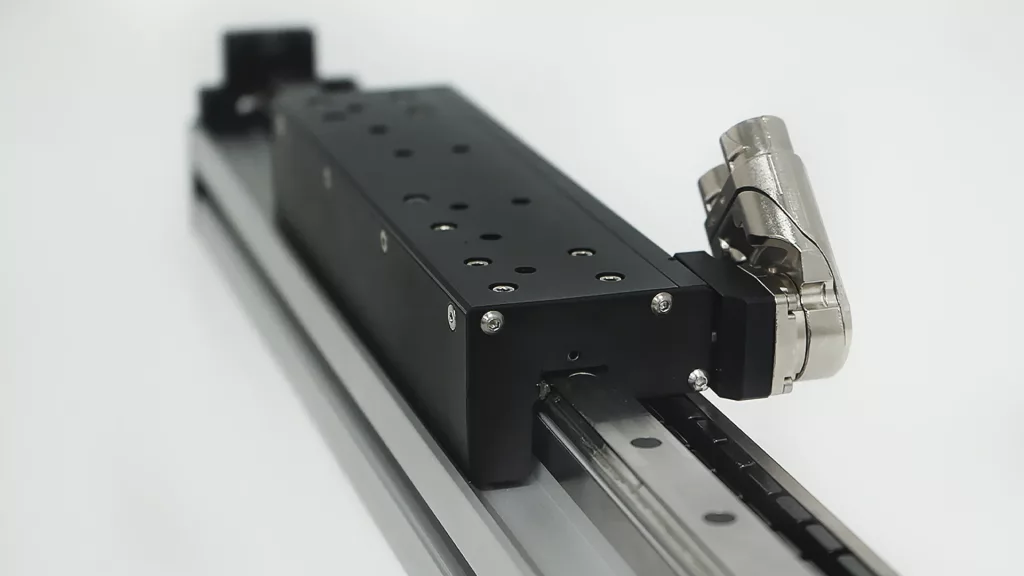

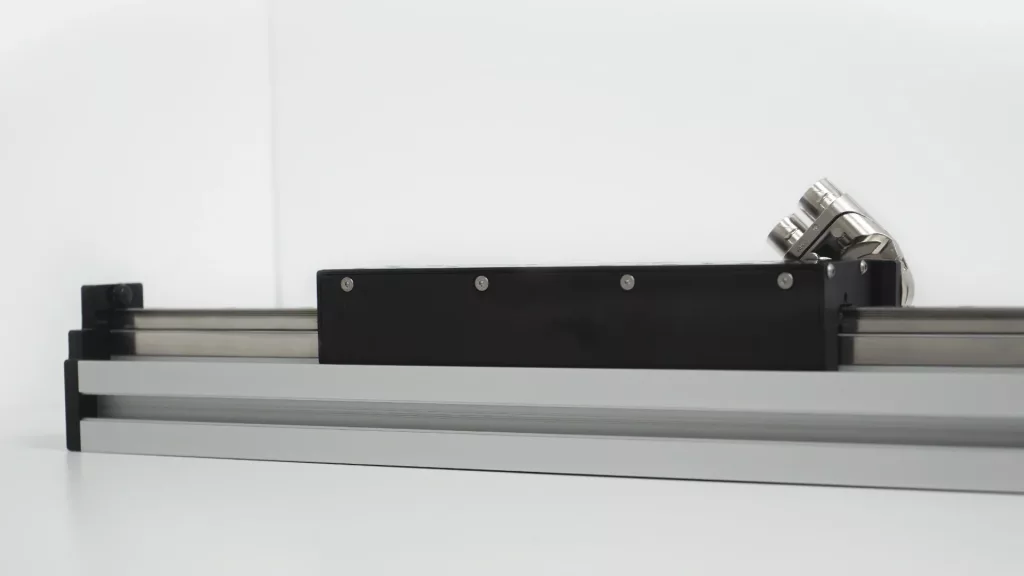

Ironless linear motor stage

Ironless linear motor stage

Ironless linear motor stage

Enhance Your Industry with Compact Linear Motor Axes

The electric motor-driven axes from SINADRIVES stand out as essential linear actuators, playing a fundamental role in positioning, assembly, and handling techniques. Their remarkable versatility and efficiency make them a preferred choice across a wide range of industrial applications.

These compact axes present an ideal solution for machines and systems where the final space becomes a critical point in the project. Thanks to their ingenious and optimized design, they maximize performance and productivity in space-constrained environments, ensuring precise and reliable execution at all times.

Capable of delivering exceptional linear displacements, these actuators drive progress and automation in various industries, from manufacturing to logistics and beyond. Their precision and adjustable speed and positioning capabilities render them indispensable for processes demanding high degrees of control and repeatability.

Moreover, SINADRIVES’ electric motor-driven axes are distinguished by their robustness and reliability, guaranteeing seamless operation and a long service life, even in demanding industrial environments.

No challenge is insurmountable for these electric motor-driven axes. From applications in electronic device manufacturing to high-precision automated systems, these actuators seamlessly adapt to meet your efficiency and quality objectives.

In summary, SINADRIVES’ electric motor-driven axes not only provide a compact and effective solution for positioning, assembly, and handling but also elevate performance and durability standards in the industrial realm. Harness the power of these linear actuators and elevate your machinery and production processes to new heights.

Get Social