In linear motor applications, selecting a suitable encoder can be the most determining factor in ensuring dynamics, precision, and, above all, reliability.

Encoder as a component for machinery automation

The speed of the servo controller’s control loop improves with the encoder’s resolution. In summary, the proper selection of the encoder plays a crucial role in the correct functioning of the application.

Take advantage of our expertise and reduce the time for selecting the right encoder, whether in terms of technology, precision, or cost. Although sometimes the application may not require high precision, having a high-resolution encoder can contribute to achieving higher dynamics.

Types of encoder solutions as available components

Currently, we offer different encoder technologies:

–Magnetic: Magnetic encoders operate uniquely by reading previously magnetized marks.

–Optical: Optical encoders use the refraction of a light beam on the measuring scale. This technology utilizes optical principles to accurately measure position changes and provides an effective solution for motion measurement in applications.

–Inductive: The scale is made of metal with machined slots at constant intervals, and the read head detects the inductance, which varies its value depending on whether there is metal or a slot on the scale.

Each of them offers certain advantages, but also limitations. Often, the environment in which the linear encoder is used determines which technology is the most suitable.

Communication protocols

Another important aspect is the compatibility with the servo controller. Communication protocols for digital buses or the type of signal for analog communications are often limited by the servo controller. Using the appropriate protocol can ensure a quick and secure startup. Additionally, it is crucial to consider the cable length, as in cases where it exceeds 15 meters, compatibility should be checked.

With the growing trend of “safe applications” according to DIN xxxxxxx standard, compatibility and expertise play an even more significant role. With our experience in the field, we ensure a quick startup.

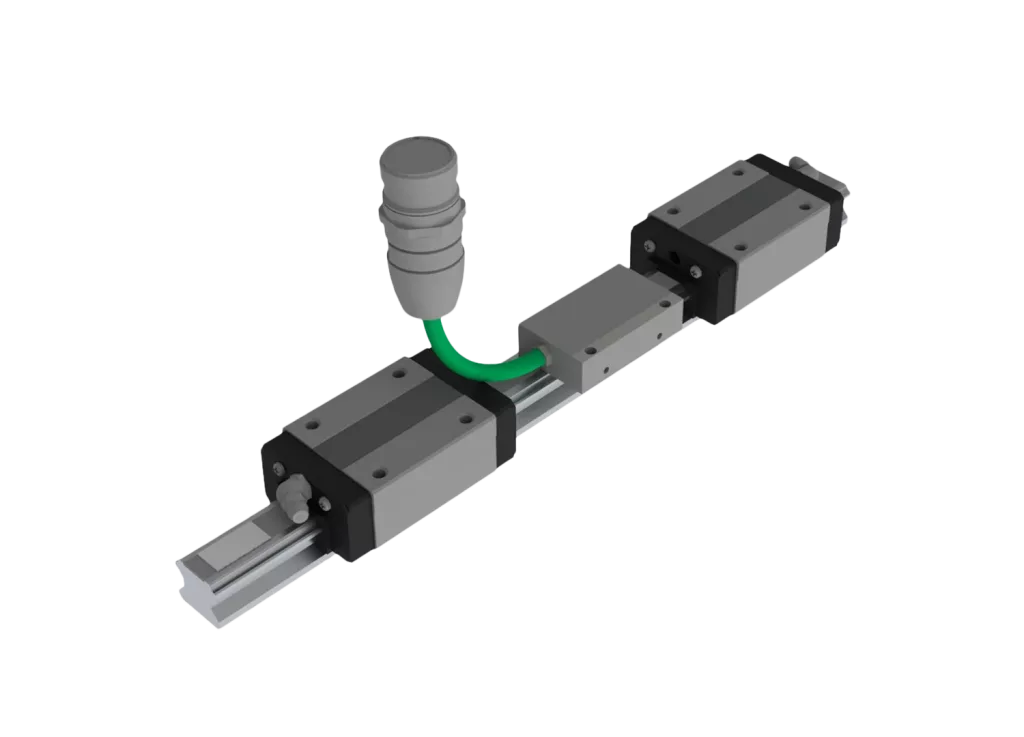

One of the unique solutions that SINADRIVES can offer is the encoder integrated into the ball guide. We have different configurations of incremental and absolute solutions, as well as a variety of communication protocols, such as Hiperfase, DSL, DriveCliq, EnDat, Panasonic, Biss, SSI, Fanuc, and Mitsubishi.

The integrated encoder solution in the guide allows machinery manufacturers to reduce design time and, above all, assembly time. This solution ensures the maintenance of the distance between the head and the scale in applications with long lengths.

Our automation components

The proper selection of an encoder as a component plays a crucial role in the correct operation of the application.

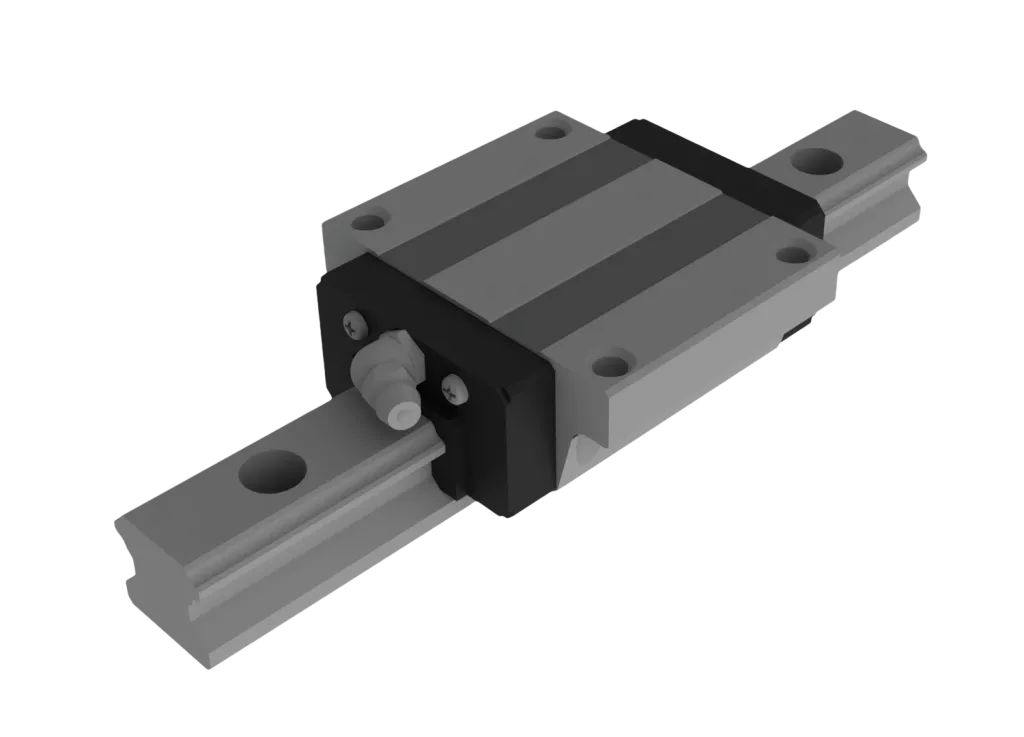

Easy installation and low maintenance, linear guides offer time savings in design and assembly.

High torque density motors with the ability to maintain constant speed under variable loads.

Get Social