On this page you will find our range of products with the latest modules and linear stages with linear motor for any type of solution. SINADRIVES has vertical and horizontal modules that can be adapted to the needs of each machine. We also have ISO 3 certified products for use in the Cleanroom.

SOLUTIONS THROUGH A LINEAR MOTOR MODULE

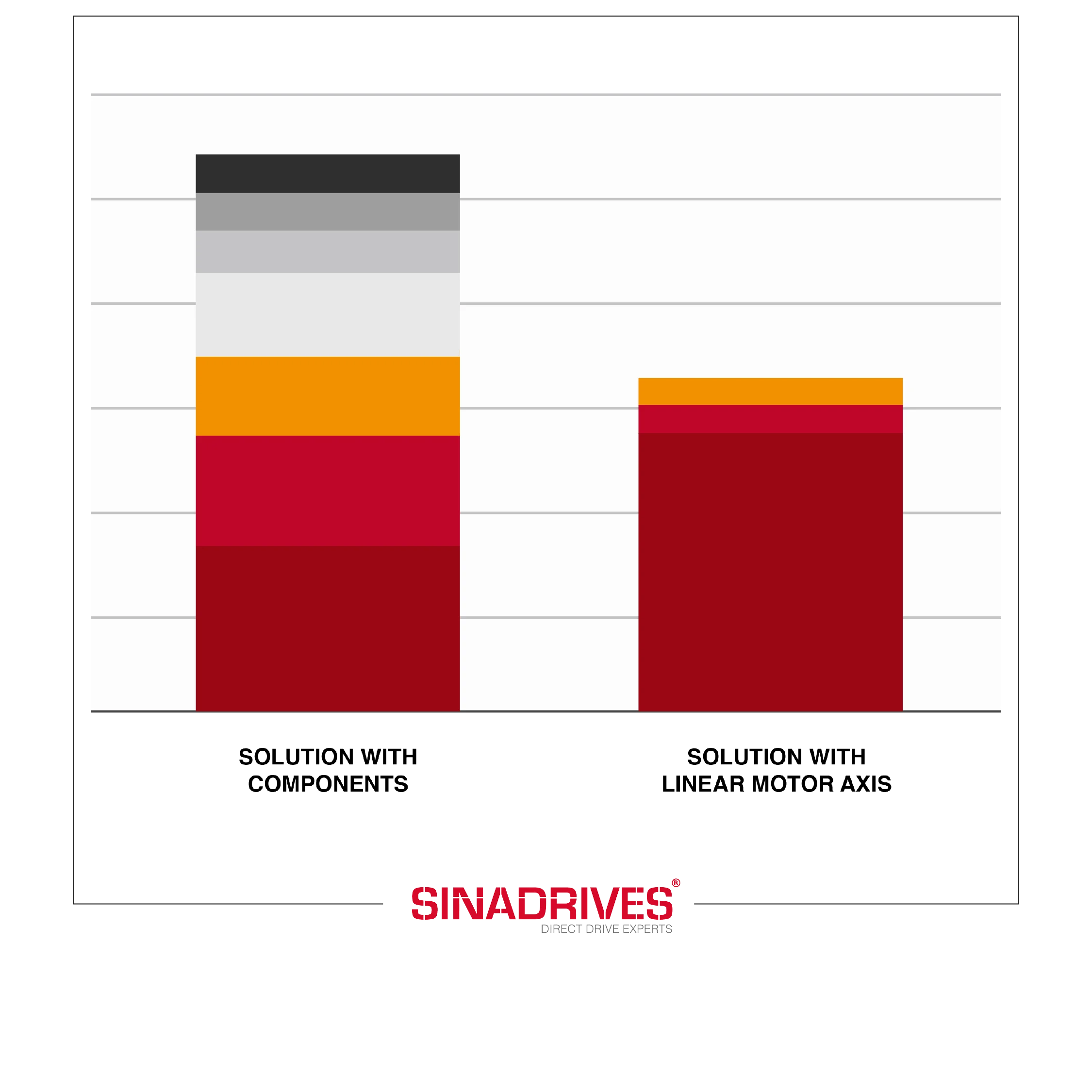

Comparison between linear motor and other transmission technologies

| Trapezoidal screw | Ball screw | Toothed belt | Rack and pinion | Linear motor | |

|---|---|---|---|---|---|

| Velocity | Low | Normal | High | High | High |

| Acceleration | Low | High | Very high | Very high | Very high |

| Precision | Normal | High | Acotada | High | High |

| Repeatability | High | High | Normal | High | High |

| Long stroke | Short | Long | Long | Long | Very long |

| Maintenance | A lot | Frequent | Low | Frequent | Very low |

How does a linear motor work?

Its versatility and distinctive characteristics make it a valuable option across a diverse array of applications, where precision, efficiency, and reliability are essential during linear motion. The linear motor capitalizes on the same fundamental principle as rotary motors, employing the interaction between magnetic fields and electric current to generate a force that propels linear movement:

Graphic representation illustrating the conversion from a rotary motor to a linear motor.

Sectors that are using our technology.

A continuación, se presentan algunos ejemplos de los diversos procesos en los cuales los fabricantes de maquinaria ya están implementando con éxito el uso del motor lineal y las mesas rotativas:

Electronics and semiconductors

Supply chain automation

Laser cutting technology

Food and beverage processing

Life Science, health and biopharma

Packaging and labeling systems

Pharmaceutical, medical and healthcare

Defense and military applications

Quality control systems

Automotive and aerospace

Printing and scanning machinery

Renewable energy and solar industry

Research and development

Textile manufacturing and production

Robotics and industrial machinery

To discover more solutions for the industry, access our SINADRIVES product page. You can also consult our site with different examples of applications in machinery from different sectors.

Get Social