Hi mechatronics fans!

Welcome to this new post in our Sinadrives blog.

March 2023

Known by various names (phasing, commutation finding, wake & shake, etc.), phasing is a key concept in servo motor control. Nevertheless, in practice it goes unnoticed, because manufacturers include it as just another parameter in their servo motor database.

As we’ll see later on in this post, during the manufacture of servomotors, the resolver is set mechanically, in order to maintain a constant lag with respect to the motor, thus saving the user from having to set it subsequently.

However, for those who need to connect motors made by a different manufacturer to the driver, and for those who wish to configure a linear motor (where this mechanical setting is not possible), this post explains the basics of phasing, along with the methods used to calculate it in practical terms. We won’t be going into complex formulas here; we’ll just be focusing on what a field engineer needs in order to get a servo motor up and running quickly and effectively.

What is phasing?

Before we dive into this concept, let’s first review how a permanent magnet servo motor works.

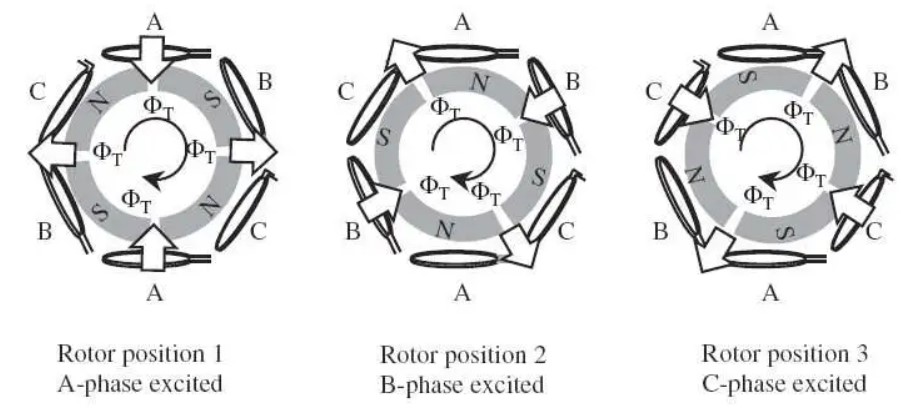

To generate motion in a three-phase motor, the windings of the motor must be energised sequentially, producing a variable magnetic field that we can control.

The winding (or phase) that receives the highest current intensity will tend to align with the corresponding magnet. As the current is switched to the next phase, this phase will push to align with the same magnet, producing a movement.

Before we dive into this concept, let’s first review how a permanent magnet servo motor works.

To generate motion in a three-phase motor, the windings of the motor must be energised sequentially, producing a variable magnetic field that we can control.

The winding (or phase) that receives the highest current intensity will tend to align with the corresponding magnet. As the current is switched to the next phase, this phase will push to align with the same magnet, producing a movement.

How to determine the phasing angle?

Conventional rotary servo motors are set in the factory when the encoder is assembled. For example, in resolver motors, one of the resolver channels is always aligned with the same motor phase, resulting in a known value.

This value is entered into the database along with the rest of the motor data, so that all the user has to do is select the motor from a list in the driver parameterisation.

This makes start-up easier when the motor and driver are made by the same manufacturer, although in practice most servo controller manufacturers incorporate functions for detecting the phasing angle when connecting third-party motors, which, if known, do not pose a major difficulty for technicians.

Although this works for a large number of applications, we are increasingly coming across situations where a driver needs to be connected to a servo motor made by another manufacturer, especially in linear motor applications, where the factory setting is not possible.

Phase detection with a Hall effect sensor

One of the most effective methods for detecting the phases of a motor is through a Hall effect sensor.

A set of three digital sensors, spaced apart at a distance equal to that between the three phases of the motor, provides information on the position of each phase with respect to the magnets.

If analogue sensors are used, only two sensors are needed, spaced at a distance equal to the gap between the magnets. The intensity of the magnetic field indicated by these sensors gives information on the position of the magnets with respect to the phases of the motor.

Although this method requires the installation of additional hardware (the Hall effect sensor itself), it only requires an initial angle detection by the driver in order to calculate the angle. This value is stored in the driver memory so that it won’t be necessary to recalculate it later on.

In addition, in the case of a repetitive application, the same assembly will retain the angle value, thus making the detection action unnecessary during the start-up of the future machines. Furthermore, it facilitates component repair and replacement, since no additional action will be required of the technician.

Phase detection according to encoder position

The drivers incorporate functions to detect the switching angle from a small movement of the motor.

For example, by consecutively energising one phase and then another, and associating these values with the relative position read through the encoder, the position of the phases and the direction of movement can be determined.

These methods do not require additional hardware, but in the case of incremental encoders this sequence has to be repeated each time the driver is switched on.

In many applications, a small movement of a few millimetres is not a problem, but in other applications, especially those with large loads or synchronised axes, it may be impossible to perform the action correctly.

This is another advantage of absolute encoders, because in this case the phasing detection action will only be executed once, after which it will be related to the absolute position of the linear axis. This makes it unnecessary to repeat the detection operation each time the driver is switched on. Nonetheless, in case of a breakdown, if the encoder is replaced, the technician will have to perform the detection operation again or the motor will not work optimally.

Conclusions

An incorrect switching angle has different effects on the servo motor. The most obvious one is when the error is considerable (more than 120°), as this will prevent it from moving or lead it to move in the opposite direction. This typically occurs when two phases of the motor are reversed in the connection with the driver.

If the error is smaller, the motor will move, but we’ll observe a higher current consumption. This will result in the overheating of the motor.

If the dynamic calculation of the application has not been carried out, or it has been done approximately, we may have the impression that a more powerful motor is required when in fact it is a parameterisation problem.

As we’ve seen, the importance of being familiar with phasing and its detection methods is not only technical; when it comes to economics and start-up times, it can mean the difference between success and failure.

If you have an application in which you’re keen to improve the performance of your machine, be it in terms of speed, dynamics, precision or simply reducing maintenance needs, please contact us.

Our specialists in Direct Drive technology and Linear Modules with linear motor technology will be happy to advise you free of charge.

Draw your own conclusions. Decide which innovation you want to implement in your machine to be competitive. We can help you.

Your SINADRIVES Team.

Get Social