Hi mechatronics fans!

Welcome to this new post in our Sinadrives blog.

October 2023

Today, we will discuss the topic of space. We increasingly need to design machines and tools that take up less space. This is particularly relevant when it comes to linear motors, as reducing moving mass further enhances dynamics.

When approaching the design of a linear or rotational motion system, one of our primary goals from the outset is to make it as compact as possible, using less material and being lighter. Once we’ve made the decision on what type of transmission to use, we start making a series of approximations and calculations to determine the size of the necessary components. This is a creative process and, at the same time, requires a greater time investment. We must find a balance between robustness and the size of the assembly we are designing. In most cases, this phase of work consumes the majority of the design time.

Linear motors, not requiring mechanical transmission systems like belts, chains, gears, or spindles, save space and reduce the need for maintenance. This is especially beneficial in applications where reliability and maintenance are critical, such as in industrial automation.

Simple design thanks to Direct Drive Technology

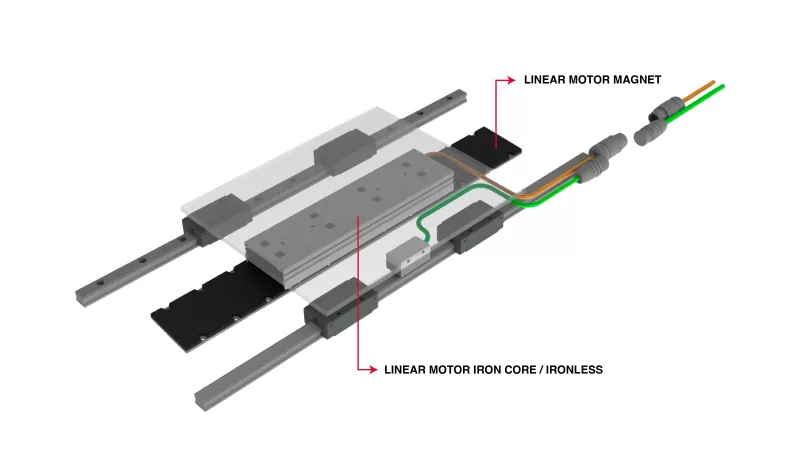

If we look at the cover image of the kit, we can notice that the solution with a linear motor is remarkably simple. The photo shows that the propulsion system based on the linear motor consists only of two components: the coil and the permanent magnet plate.

This image suggests that even an engineer with little experience would be able to implement this type of motor in their designs. Linear motors can be designed to integrate directly into a structure or system, further reducing the spatial footprint.

Scalability in power and length

Linear motors offer an excellent option to achieve different travel lengths or displacements. This is achieved by varying the length of magnetic components, such as permanent magnets. By modifying the length or quantity of these components, it is possible to change the distance that the linear motor can travel. This is valuable when different displacements are required for each application, such as in precise positioning and movement systems like printing machines or scanning systems.

The key is that it is no longer necessary to design from scratch; simply adding or removing permanent magnet plates can easily, quickly, and economically vary the stroke. At the same time, using a longer coil allows doubling or tripling the force without introducing substantial changes to the design and parts. The same applies if we opt for larger motors that only increase the width without modifying any other mechanical parameters.

Greater efficiency in physical space

Linear motors eliminate the need for rotating mechanical components, such as gears, pulleys, and spindles, significantly reducing the space required for installation. This is especially valuable in applications where space is limited, such as in the semiconductor industry or the life sciences industry (laboratory equipment).

Greater useful stroke with less length

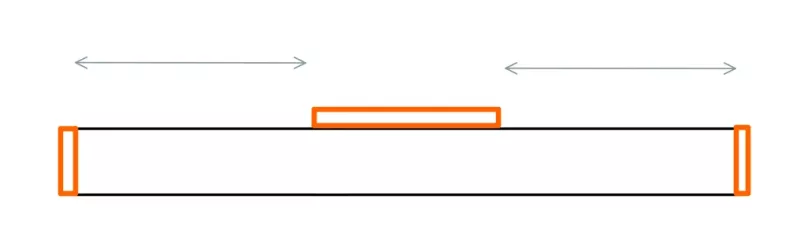

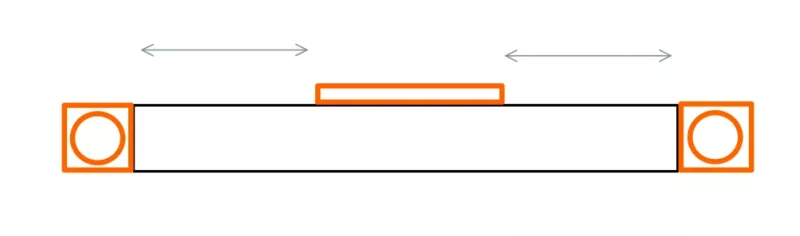

In the following image, we can compare two solutions: one with a linear motor and another with a toothed belt transmission.

Graphic representation of a linear motor stage.

Graphic representation of a toothed belt stage.

We can observe that the application of the linear motor (using the same length of the mobile carriage as a base) offers a greater useful stroke. Furthermore, if the total length needs to be shorter, we can still achieve the application without sacrificing the useful stroke.

Summary

Linear motors are a valuable technology for saving space in a variety of applications, from automotive to aerospace and medical industries, by eliminating bulky mechanical components and improving space efficiency in systems. In summary, the ability to scale in power and travel length with linear motors is a key feature that allows adapting these motors to a wide range of applications. This provides flexibility to adjust force and travel according to the demands of a specific task, which is essential in industries that require a high level of control and precision in motion.

If you have an application where you are interested in improving your machine’s performance, whether it’s speed, dynamics, precision, or simply reducing maintenance, please get in touch with us.

Our specialists in Direct Drive technology and Linear Modules with linear motor technology will be happy to advise you free of charge.

Draw your own conclusions. Decide which innovation you want to implement in your machine to be competitive. We can help you.

Your SINADRIVES Team.

Get Social