Hello, mechatronics enthusiasts!

Welcome to this new post on the SINADRIVES blog.

September 2025

In precision motion systems, engineers are often faced with a critical decision: should the application be driven by a direct-drive torque motor, or should it incorporate a motor with a gearbox? Both solutions can deliver high performance, but the choice depends heavily on the application’s requirements.

At SINADRIVES, we frequently help customers navigate this decision. Let’s break down the key differences, advantages, and trade-offs between torque motors and motor-gearbox combinations.

1. Direct-Drive Torque Motors: Power Meets Precision

A torque motor delivers high torque directly to the load without requiring mechanical transmission elements such as gearboxes or belts. This direct-drive approach offers several advantages:

- Zero Backlash: With no gears, the system achieves perfect transmission of motion, which is crucial for applications requiring absolute positioning accuracy.

- High Dynamic Response: Torque motors can accelerate and decelerate rapidly, enabling fast cycle times in automation processes.

- Low Maintenance: Without mechanical wear components like gears or belts, torque motor systems are highly reliable and require minimal maintenance.

- Smooth Motion: Ideal for applications demanding high precision and stability, such as semiconductor manufacturing, optical equipment, or high-end robotics.

While torque motors may need larger physical components compared to a small motor alone, when factoring in the space required for a gearbox in traditional setups, a direct-drive torque motor system is often more compact overall.

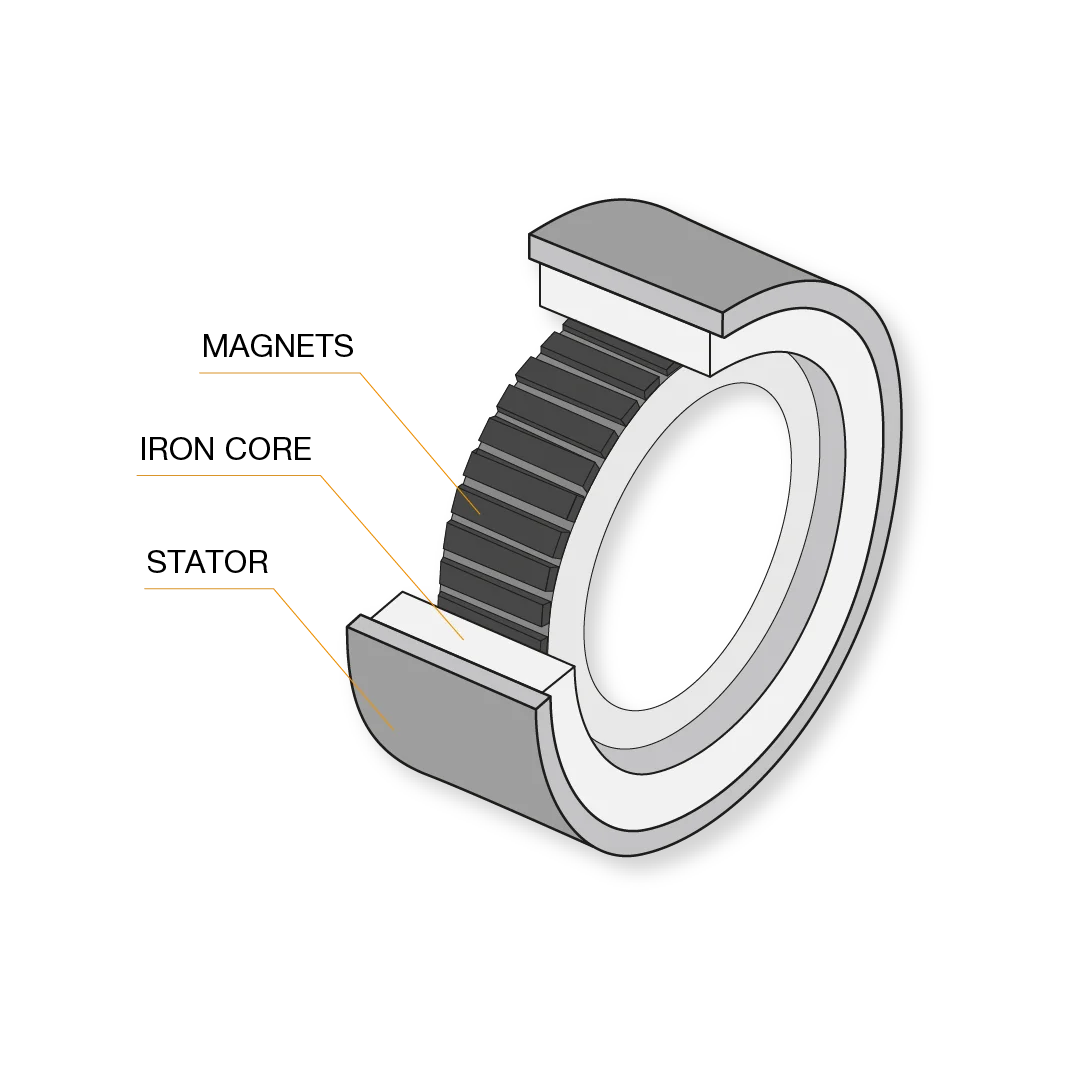

Ironcore torque motor

Anatomy of an ironcore torque motor

Ironless torque motor

Anatomy of an ironless torque motor

2. Motors with Gearboxes: A Compromise Solution

Using a motor with a gearbox can multiply torque through gear reduction, enabling a smaller motor to deliver more output torque. While this approach can work in some cases, it comes with clear trade-offs:

- Torque Increase Through Gear Reduction: A gearbox lets a small motor reach higher torque levels, but the combined size is often bulkier than a direct-drive solution.

- Application-Specific Efficiency: Gearbox systems may perform reasonably well in steady, constant-load conditions — but outside these ranges, efficiency drops significantly.

- Lower Upfront Cost: Gearboxes can reduce initial investment, though ongoing maintenance costs often outweigh this benefit.

- Compact High Torque: Useful when high torque is needed, but only if some loss of accuracy and smoothness is acceptable.

⚠️ Despite these points, gearboxes introduce backlash, noise, mechanical wear, and maintenance requirements, all of which limit precision, reliability, and long-term performance.

Why Direct Drive is the Better Choice

For most modern applications, direct-drive torque motors provide a cleaner, more robust, and more efficient solution.

Choose direct-drive torque motor if your application requires:

- Extreme positioning accuracy without backlash

- High dynamic response and smooth motion

- Long service life with minimal maintenance

- Superior energy efficiency over time

- Reliability in demanding, high-precision environments

Only consider a motor with gearbox if your application has:

- Lower accuracy requirements

- Budget restrictions that outweigh performance needs

- Acceptance of some backlash and higher maintenance

SINADRIVES: Your Partner in Motion Precision

At SINADRIVES, we specialize in helping customers achieve the perfect balance between performance and efficiency. Whether you are building a system that demands nanometer-level accuracy or a cost-optimized industrial solution, our experts can guide you in selecting the ideal drive technology.

If you are unsure whether your application is better suited for a torque motor or a motor-gearbox configuration, our team can provide detailed consultation and customized solutions.

Contact us today to discover which technology best fits your project.

Get Social