The assembly consists of a direct-drive motor integrated in the aluminium housing, crossed-roller bearings, a high-precision encoder and connectors. This complete assembly is ready to be connected to a servo drive.

DISCOVER THE SINADRIVES RANGE OF ROTARY TABLE SYSTEMS

FLAT MRT020001-F

Features of the MRT020001 – F Motor

D (mm): 102

d (mm): –

H (mm): 40

Nominal torque (Nm): 0,5

Peak torque (Nm): 1,2

Encoder type: absolute.

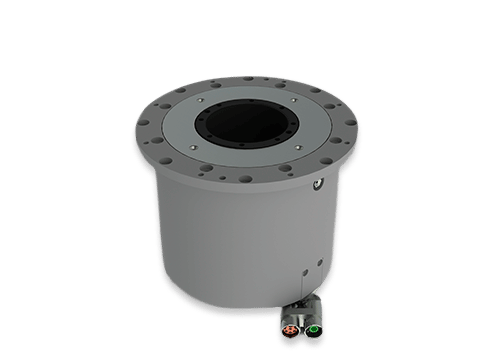

Model MRT020005

Features of the MRT020005 Torque Motor

D (mm): 94

d (mm): 20

H (mm): 90

Nominal torque (Nm): 1,97

Peak torque (Nm): 4,54

Encoder type: absolute.

Model MRT030028

Features of the MRT030028 Torque Motor

D (mm): 122

d (mm): 42

H (mm): 155

Nominal torque (Nm): 10,80

Peak torque (Nm): 28,40

Encoder type: absolute.

Model MRT040056

Features of the MRT040056 Torque Motor

D (mm): 152

d (mm): 60

H (mm): 131

Nominal torque (Nm): 19,7

Peak torque (Nm): 55,5

Encoder type: absolute.

Model MRT060173

Features of the MRT060173 Torque Motor

D (mm): 230

d (mm): 125

H (mm): 138

Nominal torque (Nm): 58,50

Peak torque (Nm): 173

Encoder type: absolute.

This complete assembly is ready to be connected to a servo drive. It should be noted that thanks to the mechanical configuration with a through bore, the machinery manufacturer can thread cables, tubes and other devices through it that are necessary for the application.

Main advantages of using rotary tables

Advantage 1: Save space in the machine with the high force density of these motors. Thanks to their unique design, these motors offer an enormous force density compared to traditional servo motors. The multipolar technology reduces the size of a rotary table by approximately 50% compared to the size of a conventional servo motor.

Advantage 2: Position loads with a high inertia ratio thanks to the high-resolution encoder. The built-in high-resolution encoder enables precise control of the application, even when the inertia ratio of the load is greater than 5:1.

Advantage 3: Reduce maintenance and increase availability. Direct Drive technology has no wear and tear. The motion generation is done through an electromagnetic field, without contact, and as a result, requires no maintenance.

Comparison between different rotary technologies

The table compares three types of motors: Rotary Table, Zero Backlash Motor, and Planetary Gear Motor. Here is a summary of their characteristics:

| Rotary Table | Zero Backlash Motor | Planetary Gear Motor | |

|---|---|---|---|

| Backlash | 0 | 0 | 0,1167º |

| Size | Standard | +50% | +50% |

| Efficiency | 99% | 70% | 90% |

| Maintenance | Very low | High (additional cost for replacements) | High (additional cost for replacements) |

| Hollow Shaft | Yes | No | No |

| Rigidity | +50% | Standard | Standard |

The rotary table stands out for its high efficiency, compact size, and low maintenance, while the other two types of motors offer inferior characteristics that may be useful for simpler workloads.

MRT020001 – F Rotary table

MRT020001 – F Rotary table

MRT020001 – F Rotary table

MRT020005 Rotary table

MRT020005 Rotary table

MRT020005 Rotary table

MRT030028 Rotary table

MRT030028 Rotary table

MRT030028 Rotary table

Why should I choose a rotary table system from SINADRIVES?

Enhance your machine’s performance with the expertise of the market leader in Direct Drive technology.

Reduce space and maintenance requirements with modern and cost-effective technology.

Minimize assembly times and mechanical adjustments with the most compact brushless motor technology in the market.

Sectors that are using our technology.

Below are some examples of the diverse processes in which machinery manufacturers are successfully implementing the use of linear motors and rotary tables:

Electronics and semiconductors

Supply chain automation

Laser cutting technology

Food and beverage processing

Life Science, health and biopharma

Packaging and labeling systems

Pharmaceutical, medical and healthcare

Defense and military applications

Quality control systems

Automotive and aerospace

Printing and scanning machinery

Renewable energy and solar industry

Research and development

Textile Manufacturing and production

Robotics and industrial machinery

Get Social